About this product

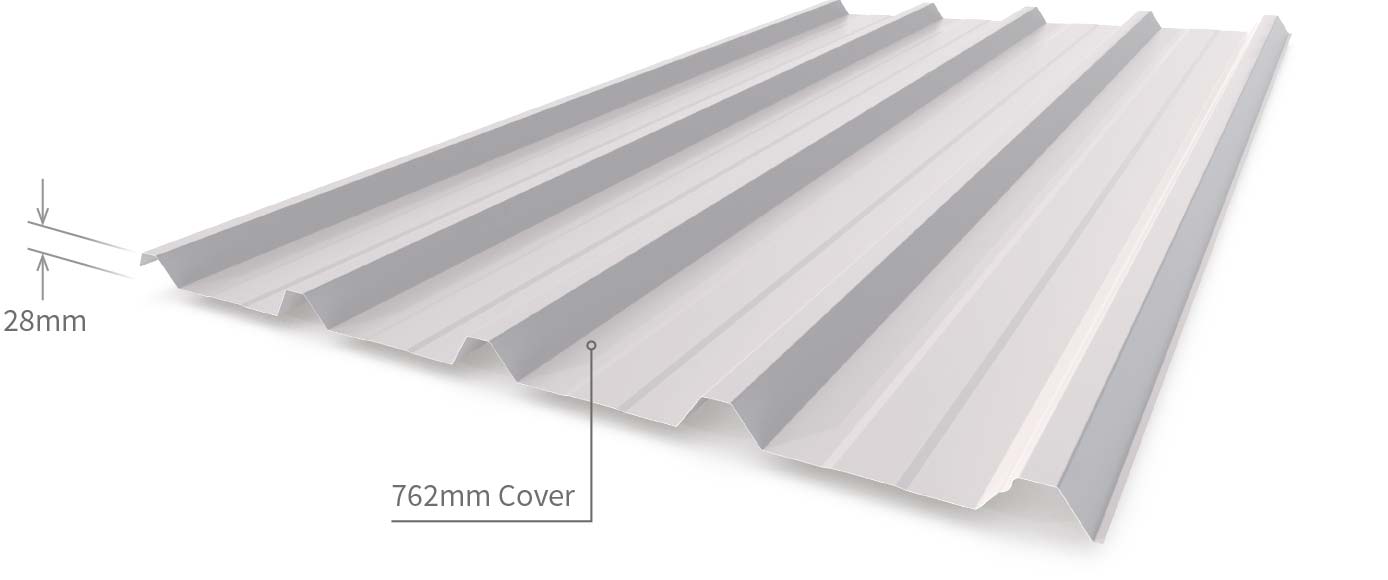

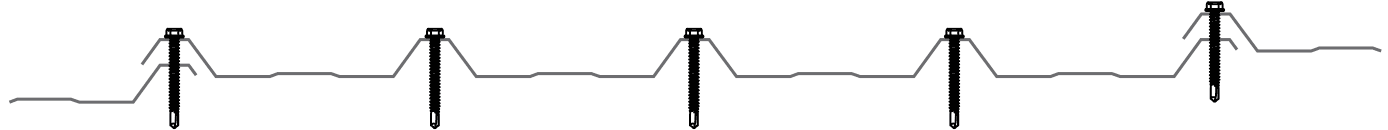

The trapezoid profile of Superdek roofing, walling and fence cladding endows a high tensile sheet strength. It is suitable for domestic and low cost industrial cladding.Image gallery

Versatile Superdek Steel Cladding

Superdek has a sharp, modern appearance, combined with strength and versatility.

Superdek has a 28mm rib height that allows for long spans and delivers outstanding water carrying ability. Installers recommend Superdek because its pierce fixed installation is fast and easy. Its lightweight, rigid design allows purlins to be widely spaced, making Superdek a very economical and efficient material to use.

Superdek has a trapezoidal profile with an anti-capillary rib on the under-lap, which provides weather tightness and the ability to perform well at low roof pitches. This design feature makes Superdek the prime roofing and walling choice for many medium sized commercial projects. Superdek is also ideal for fencing, where its bold rib shape provides an attractive appearance.

Available Colours

Brochures & Installation Guides

Custom Made For Your Project

Superdek cladding longer than 1.2 metres are rolled to the specific length you require, provided satisfactory transport and handling facilities can be arranged. If lengths longer than ten metres are required, consult Stratco for advice on handling and transport.

To give your roof a professional finish, painted self-drilling screws are available. Stratco offer a complete range of flashings and accessories for use with Superdek, and can provide professional advice on specific flashings.

Compliance

The Wind Capacity Tables are based on testing in accordance with AS1562.1-1992 and AS4040.0, 1 & 2-1992. Span tables have been developed by determining wind pressures in accordance with AS4055-2006 for domestic applications and AS/NZS 1170.2:2002 for all other applications. Capacity tables are in limit state format.

Ordering Superdek Cladding

Sheets are available custom cut, allowing you to minimise waste, and enhance your design options. Superdek is available in un-painted zinc/al, and in an attractive range of factory pre-painted colours. Subject to the delivery location, quantity and material availability, delivery is usually within 48 hours, or at an agreed time that suits your building schedule. Unless advised differently, a one tonne maximum is usually applied to larger packs. Arrangements for unloading the truck are the responsibility of the customer, and should be arranged before ordering. When unloading you must ensure the load is adequately spread using spreaders and slings to prevent damage. If packs are to be loaded above structural members, they must be of sufficient strength, such as over portal frames, or braced roof trusses.

Design Considerations

The minimum roof pitch for Superdek is two degrees (1 in 30). The 762mm coverage provides easy handling and installation. Superdek roofing is subject to thermal expansion, particularly on darker colours. The maximum length before an expansion joint is required is 24 metres for lighter colours, and 16 metres for darker colours.

| Material Properties | Finish | 0.35 BMT | 0.42 BMT | 0.48 BMT |

| Total Coated Thickness (TCT) mm | Zinc/alum | 0.40 | 0.47 | 0.53 |

|---|---|---|---|---|

| Colour | 0.43 | 0.50 | 0.56 | |

| Mass (kg / linear metre) | Zinc/alum | 2.74 | 3.26 | 3.70 |

| Colour | 2.79 | 3.32 | 3.76 | |

| Mass (kg / square metre) | Zinc/alum | 3.60 | 4.28 | 4.86 |

| Colour | 3.67 | 4.35 | 4.93 | |

| Yield (square metre / tonne) | Zinc/alum | 277.9 | 233.8 | 205.9 |

| Colour | 272.3 | 229.8 | 202.8 | |

| Tensile Strength (MPa) | Zinc/alum & Colour | 550 | 550 | 550 |

| Width Coverage (mm) | Zinc/alum & Colour | 762 | 762 | 762 |

| Sheet Tolerances (mm) | Length & Width | ±5 ±2 | ±5 ±2 | ±5 ±2 |

| Minimum Roof Pitch | Zinc/alum & Colour | N/A | 2° | 2° |

Spans

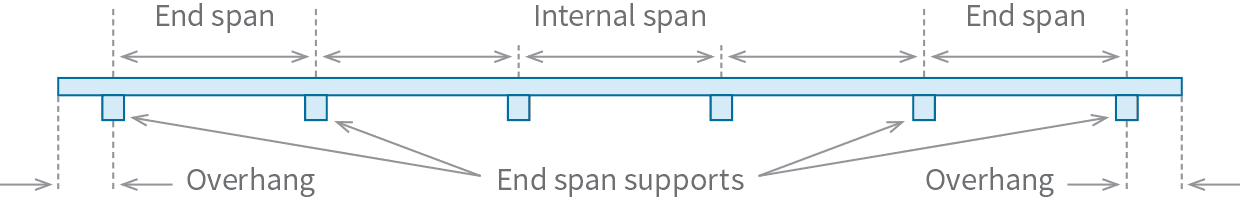

Spans are determined by wind speeds for non-cyclonic areas. For domestic applications, the pressures and spans are based on a maximum: eaves height of six metres, roof pitch of 35 degrees and total roof height of 8.5 metres. For commercial and industrial applications, tables are based on a maximum overall height of ten metres and a 500 year design return period.

Roofing calculations are based on Cpe=-0.9 and Cpi=0.2, walling is based on Cpe=-0.65 and Cpi=0.2. A local pressure factor, Kl=2.0 has been used for all roofing and walling spans for both strength and serviceability limit states. Roof spans allow for loads incidental to maintenance.

All pressures have been determined assuming the wind loading in any direction is not affected by topography. The following shielding factors have been used for each of the terrain categories: Category 3 = 0.85, Category 2.5 = 0.95, and Category 2 = 1.

The carport and verandah spans only apply to structures not enclosed by peripheral walls. Spans are based on Cpn=-0.9 and Kl=1.5 applied over the entire span, and are suitable for all span types. Loads on supporting purlins may limit these spans.

Stratco can provide additional engineering advice if any design parameters vary from those above.

Material Specifications

| Material Specifications | ||||||

| BMT | Application | Span Type | N1 (W28) | N2 (W33) | N3 (W41) | N4 (W50) |

|---|---|---|---|---|---|---|

| 0.35 | Walling | Single | 1700 | 1700 | 1600 | 1450 |

| End | 2200 | 2200 | 2000 | 1550 | ||

| Internal | 2500 | 2500 | 2250 | 1700 | ||

| 0.42 | Roofing | Single | 1150 | 1150 | 1150 | 1150 |

| End | 1350 | 1350 | 1350 | 1350 | ||

| Internal | 1900 | 1900 | 1900 | 1500 | ||

| Walling | Single | 2350 | 2100 | 1850 | 1700 | |

| End | 2850 | 2550 | 2250 | 1700 | ||

| Internal | 3000 | 3000 | 2600 | 1950 | ||

| 0.48 | Roofing | Single | 1700 | 1700 | 1700 | 1500 |

| End | 1900 | 1900 | 1900 | 1500 | ||

| Internal | 2600 | 2600 | 2350 | 1800 | ||

| Walling | Single | 2800 | 2400 | 2000 | 1950 | |

| End | 3200 | 2950 | 2550 | 2050 | ||

| Internal | 3300 | 3300 | 2900 | 2250 | ||

The values in all of the above tables are for use with steel supports with a minimum thickness of 0.75mm, G550.

Maximum Recommended Spans

| Maximum Recommended Spans (mm) | |||||

| Span Type | Roofing (BMT) | Walling (BMT) | |||

|---|---|---|---|---|---|

| 0.42 mm | 0.48 mm | 0.35 mm | 0.42 mm | 0.48 mm | |

| Single Span | 1150 | 1700 | 1700 | 2350 | 2800 |

| End Span | 1350 | 1900 | 2200 | 2850 | 3200 |

| Internal Span | 1900 | 2600 | 2500 | 3000 | 3300 |

| Un-stiffened Overhang | 200 | 250 | 150 | 200 | 250 |

| Stiffened Overhang | 300 | 350 | 300 | 300 | 350 |

Roofing spans are limited, based on typical maintenance foot traffic. Walling spans are based on N1 (W28) wind loading. The values are for use with steel supports with a minimum thickness of 0.75mm, G550.

Domestic Carport / Patio Spans

| Domestic Carport / Verandah Spans (mm) | ||

| Wind Classification | Base Metal Thickness | |

|---|---|---|

| 0.42 mm | 0.48 mm | |

| N1 (W28) | 2400 | 2700 |

| N2 (W33) | 2400 | 2700 |

| N3 (W41) | 1900 | 2100 |

| N4 (W50) | 1500 | 1700 |

The values are for use with steel supports with a minimum thickness of 0.75mm, G550.

Wind Load Conversion

For domestic applications use the appropriate wind classification for the area. To read the span tables for commercial and industrial applications, select the region and category for the area, then convert it to the correct classification using the table below.

| Wind Load Conversion | |

| Wind Classification (Domestic) |

Region and Category (Commercial / Industrial) |

|---|---|

| N1 (W28) | Region A, Category 3 |

| N2 (W33) | Region A, Category 2.5 - Region B, Category 3 |

| N3 (W41) | Region A, Category 2 - Region B, Category 2.5 |

| N4 (W50) | Region B, Category 2 |

Wind Capacities

| Wind Capacities (kPa) | ||||||||||||

| BMT | Span Type | Limit State | 900 | 1200 | 1500 | 1800 | 2100 | 2400 | 2700 | 3000 | 3300 | 3600 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.35 | Single | Serviceability | 2.19 | 1.68 | 1.36 | 1.06 | 0.76 | 0.45 | - | - | - | - |

| Strength | 6.64 | 4.83 | 3.06 | 2.61 | 2.14 | 1.67 | - | - | - | - | ||

| End | Serviceability | 2.45 | 2.08 | 1.86 | 1.64 | 1.30 | 0.95 | 0.61 | 0.27 | - | - | |

| Strength | 6.50 | 5.00 | 3.75 | 2.50 | 2.17 | 1.83 | 1.50 | 1.17 | - | - | ||

| Internal | Serviceability | 3.68 | 2.68 | 2.10 | 1.53 | 1.33 | 1.14 | 0.94 | 0.75 | - | - | |

| Strength | 6.67 | 5.33 | 4.21 | 3.08 | 2.69 | 2.29 | 1.90 | 1.50 | - | - | ||

| 0.42 | Single | Serviceability | 3.72 | 2.64 | 1.73 | 1.33 | 0.94 | 0.55 | 0.39 | 0.23 | - | - |

| Strength | 7.18 | 5.42 | 4.17 | 3.53 | 2.89 | 2.25 | 1.88 | 1.50 | - | - | ||

| End | Serviceability | 4.59 | 3.64 | 2.68 | 1.73 | 1.41 | 1.09 | 0.77 | 0.45 | - | - | |

| Strength | 6.23 | 5.04 | 4.10 | 3.17 | 2.81 | 2.46 | 2.10 | 1.75 | - | - | ||

| Internal | Serviceability | 5.61 | 4.33 | 3.15 | 1.98 | 1.67 | 1.36 | 1.18 | 1.00 | - | - | |

| Strength | 7.15 | 5.58 | 4.58 | 3.58 | 3.19 | 2.79 | 2.40 | 2.00 | - | - | ||

| 0.48 | Single | Serviceability | - | 3.55 | 2.73 | 1.91 | 1.09 | 0.95 | 0.80 | 0.65 | 0.51 | 0.36 |

| Strength | - | 6.61 | 5.79 | 4.98 | 4.17 | 3.58 | 3.00 | 2.42 | 1.83 | 1.25 | ||

| End | Serviceability | - | 4.36 | 3.43 | 2.50 | 1.57 | 1.35 | 1.13 | 0.91 | 0.69 | 0.47 | |

| Strength | - | 5.21 | 4.57 | 3.93 | 3.29 | 2.97 | 2.64 | 2.32 | 1.99 | 1.67 | ||

| Internal | Serviceability | - | 4.64 | 3.79 | 2.94 | 2.09 | 1.61 | 1.40 | 1.18 | 0.97 | 0.75 | |

| Strength | - | 5.92 | 5.21 | 4.50 | 3.79 | 3.08 | 2.77 | 2.46 | 2.15 | 1.83 | ||

The values are for use with steel supports with a minimum thickness of 0.75mm, G550.

Water Carrying Capacity

| Maximum Roof Run For Drainage (m) | ||||||||

| Roof Slope | Peak Rainfall Intensity (mm/hr) | |||||||

|---|---|---|---|---|---|---|---|---|

| 150mm/hr | 180mm/hr | 200mm/hr | 250mm/hr | 300mm/hr | 350mm/hr | 400mm/hr | 450mm/hr | |

| 2° | 130 | 108 | 97 | 78 | 65 | 55 | 48 | 43 |

| 3° | 151 | 126 | 113 | 90 | 75 | 64 | 56 | 50 |

| 5° | 185 | 154 | 139 | 111 | 92 | 79 | 69 | 61 |

| 7.5° | 221 | 184 | 166 | 132 | 110 | 94 | 83 | 73 |

| 10° | 251 | 209 | 188 | 151 | 125 | 107 | 94 | 83 |

| 15° | 304 | 253 | 228 | 182 | 152 | 130 | 114 | 101 |

The peak rainfall intensities shown represent a 100 year average recurrence interval (ARI) for a five minute rainfall duration. If roof penetrations exist, the total roof run will generally be greater than the distance from ridge to eaves at the location the penetration interferes with the runoff. Contact Stratco if further advice is required.

Fixing Recommendations

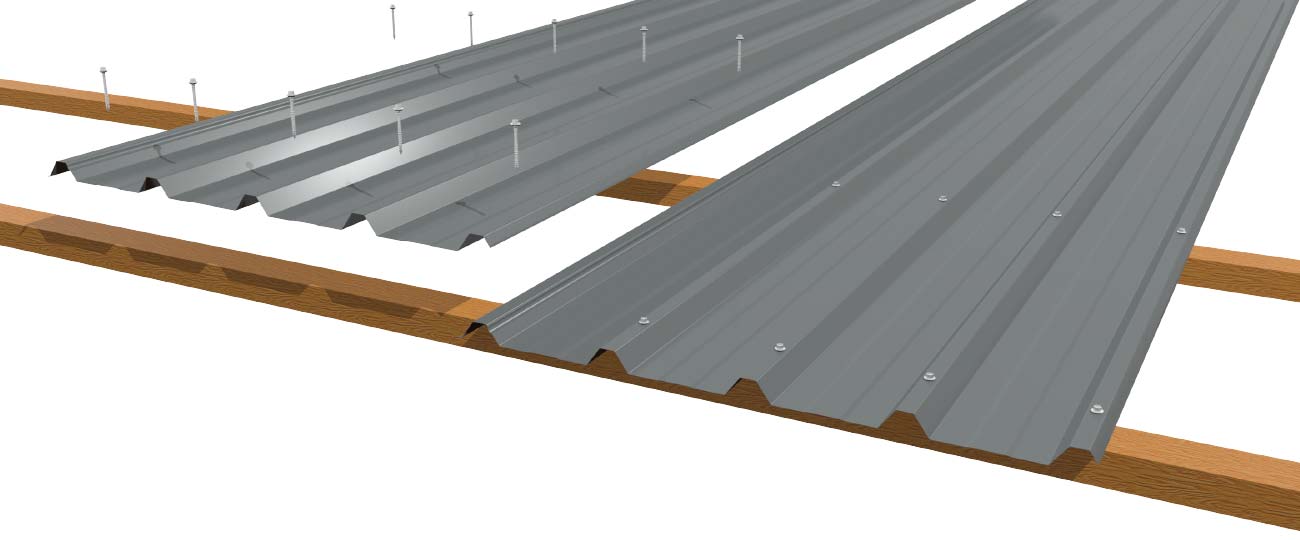

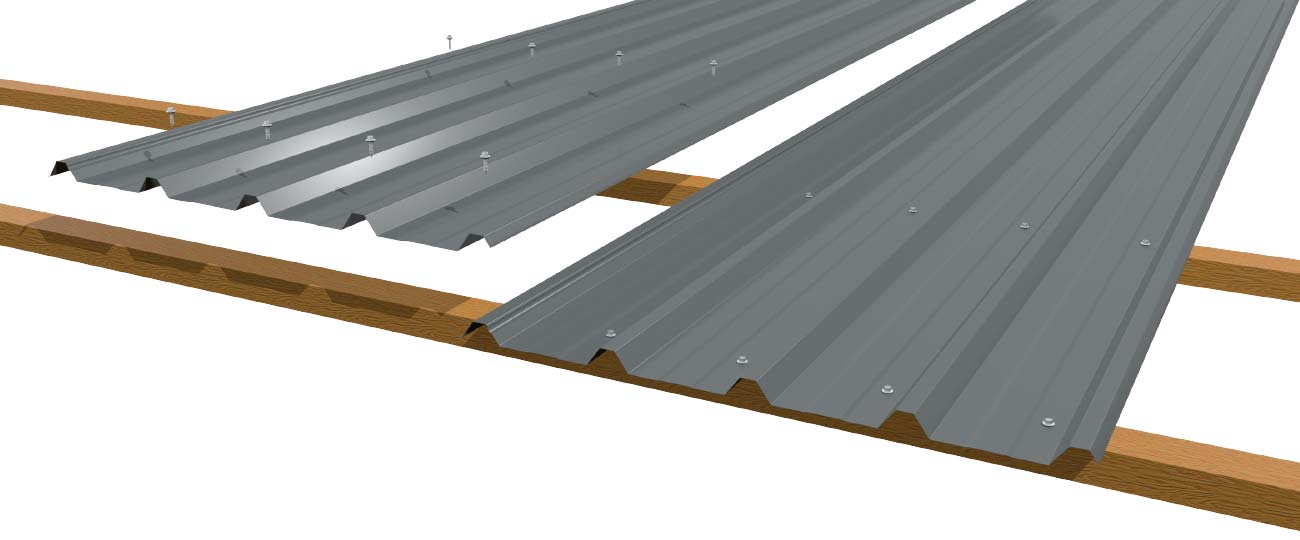

Superdek sheets should be laid into the prevailing wind and sit neatly on the preceding roof sheet, as shown in the laying procedure below. They should be fixed at the recommended support spacings. Avoid ‘stretching’ the width of the sheet when installing, as this could allow wind and rain to enter. Due to its higher rib height, flashing turn downs into the pan of Superdek should always be notched around the rib to provide maximum weather tightness.

Pan fixing is only suitable for walling, carport and verandah applications or where weather tight roofing is not essential. When spans exceed 900mm for roofing or 1200mm for walling, it is recommended the side laps are fixed at mid-span to ensure a weatherproof seal and to secure the overlap, especially when the roof is walked on occasionally. Use either 8 x 12mm self drill stitching screws or 3.2mm sealed blind rivets. On roofing, at the end of the sheets, the pans should be turned up at crest of the roof and down into the gutter using a turn up/down tool.

Roof Laying Procedure

Prevailing Wind →

← Laying Direction

Wall Laying Procedure

Prevailing Wind →

← Laying Direction

Fastener Selection

Fixing to Steel Roofing

12 x 45mm or TS M6 x 50mm* self drilling and tapping screw with neoprene washer

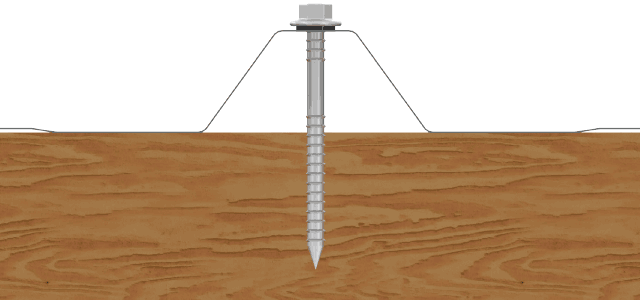

Fixing to Timber Roofing

12 x 65mm type 17 hex head screw or M6 x 65mm TS self-drilling screw with neoprene washer

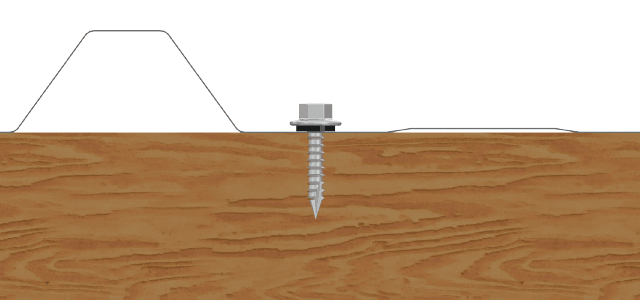

Fixing to Steel Walling

10 x 16mm self drilling and tapping screw with neoprene washer

Fixing to Timber Walling

10 x 25mm type 17 hex head screw with neoprene washer

*When fixing to 0.55mm thick roof battens; crest fix with M6 x 50mm TS self drilling screws with neoprene washers. Indicated spans will still apply.

The above screw sizes can be fixed over an insulation blanket up to 55mm thick, for thicknesses up to 100mm, use the next screw length to that shown.

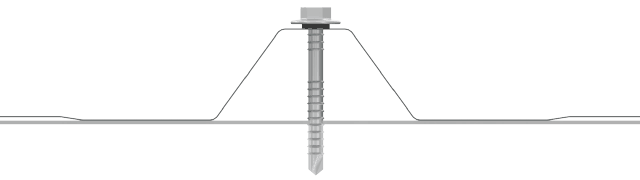

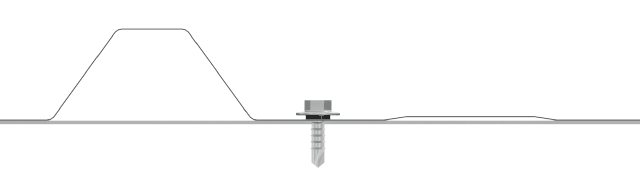

Fastener Positions

Roofing - One Fixing Per Crest

Walling - One Fixing Per Pan

Fasten adjacent to the overlapping rib.

Walking on Superdek

When walking on Superdek roofing, it is recommended you walk over the purlins to avoid any damage. Wear flat, rubber soled shoes and walk flat footed in the sheet pans only. For carport and verandah applications, use crawl boards to avoid damage during installation and maintenance.

Using Superdek

Stratco Superdek will have a long, useful life if used according to Stratco specifications. While roofing materials in outer urban and rural areas may have a life-span in excess of 30 years, this can reduce to only a few years in coastal and industrial environments.

Zinc/al and pre-painted steel should not be used in very aggressive areas such as near swimming pools and spas. It is important that dirt, soil, compost, paving sand, or other materials which retain moisture are not placed against steel sheeting. Concrete should not be poured against zinc/al material. Check with Stratco before using in these severe environments.

Incompatible Metals

The best way of reducing corrosion is to keep incompatible metals apart. Zinc/al and pre-painted steel cannot be used with lead, copper and monel. Galvanised steel and pure zinc material can be used with zinc/al, but you must avoid water run-off from zinc/al onto galvanised material. Fixings such as rivets and self-drilling screws must be compatible with the material they are fixing.

Handling and Cutting of Superdek

For safety, wear gloves when handling Superdek. Ensure your hands or gloves are clean, especially when handling zinc/al which can mark. Use a coloured pencil for marking steel, as lead or black pencils contain graphite which promotes rusting. Superdek is best cut using tin snips, but for larger cuts it may be necessary to use a power saw with a steel cutting blade or a power nibbler. Avoid using abrasive discs as they can cause burred edges and coating damage. Where possible cut sheets on the ground, and always clean off any swarf and metal filings progressively during the installation. Dispose of off-cuts carefully.

Insulation and Sealants

The use of blanket insulation is recommended in domestic roofing to assist in temperature, condensation and sound control. Superdek can be used with an insulating blanket up to 55mm thick. Increased thicknesses require longer fasteners and greater care when installing.

When choosing a silicone sealant, ensure it is suitable for roofing and guttering use and of a non-acetic, amine free, neutral cure type. Sealants that smell of ammonia, vinegar or lemons are not usually suitable.