CGI Spring-Curving

StratcoSKU: CGI-Spring-Curving

Curved creations are made possible with a range of cladding profiles from Stratco that support the ability to be spring-curved. Clean lines and sweeping arcs are achieved with the flexibility of spring-curved roof and wall cladding. This style of roofing can be ordered to suit your exact requirements. Whether you want to install it yourself or require assistance, we are here to help. Contact us for pricing and further details today.Image gallery

Flowing Curves and Sweeping Arcs

Expand your architectural creativity with spring-curved cladding.

Spring-Curved Cladding from Stratco allows you to expand your architectural creativity by incorporating sweeping arcs and flowing curves into roof and wall cladding designs.

Spring-curving refers to cladding that is supplied flat, and has the ability to be fixed over a curved structure. Stratco offers three profiles that can be convex spring-curved; Smartspan®, CGI Corrugated and CGI Curving. And five profiles that can be concave spring-curved; Smartspan®, CGI Corrugated, CGI Curving, Superdek® and Topdek® 700.

Available Colours:

Brochures & Installation Guides

Spring-Curving Considerations

Stratco manufacture continuous lengths of roof sheeting that can be laid from eave to eave across the full width of the roof. The following precautions should be considered for this type of roof construction:

- Roof slopes for each of the roofing profiles shown in tables on the 'Technical Information' tab are not to be exceeded.

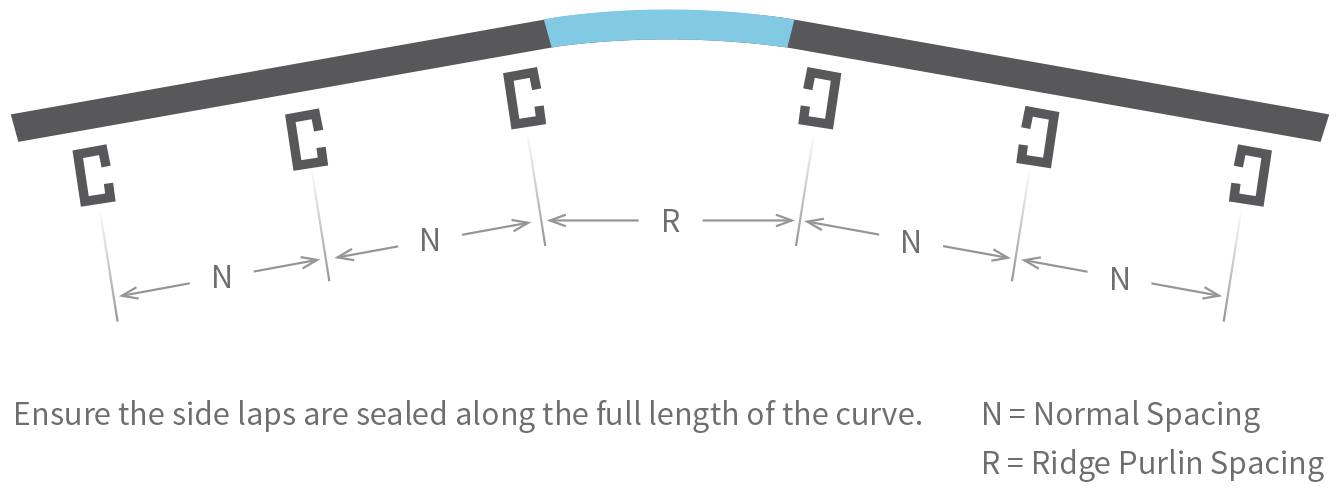

- Spacing between the ridge purlins are as shown in tables on the 'Technical Information' tab.

- Where a ridge board is used in the roof construction the top face should not be higher than the line of curvature that the roof sheeting will assume between the ridge purlins.

- Side laps are to be sealed along the full length of the curvature, between the two centre purlins.

- Slight crease marks may occur in the pans of the roof profile between the ridge purlins or roof battens when subject to foot traffic.

Profile

Material Specifications

| Minimum Ridge Purlin Spacing For Spring Curved Ridges | |||||

| Maximum Roof Slope |

Smartspan® BMT | CGI Corrugated BMT | CGI Curving BMT | ||

|---|---|---|---|---|---|

| 0.42mm | 0.48mm | 0.42mm | 0.48mm | 0.60mm | |

| 1 in 20 (3°) | 1400 | 1500 | |||

| 1 in 15 (4°) | 1500 | 1600 | |||

| 1 in 12 (5°) | 1700 | 1200 | 1300 | 1200 | |

| 1 in 10 (6°) | 1400 | 1300 | |||

| 1 in 8 (7°) | 1400 | ||||

Note: If oil canning in pans is considered acceptable, concealed fix decks such as Topdek® 700 can be spring curved over a ridge up to a maximum slope of 1 in 30 (2°) providing the spacing between the ridge purlins are slightly less than Stratco’s recommended internal spans. Please refer to Spring Curving in the Stratco Technical Guide for further information.

Spring Curved Convex Roofing

Using the overall width plus the rise of a convex roof, the radius of curvature can be calculated using the equation shown in the diagram below. The side laps of convex roofs are to be sealed using a recommended sealant. This is required at the roof crest where the slope is less than the recommended minimum for each roofing profile. However, care must be taken to ensure the sheets anti-capillary drain is not blocked. The length of roof to be sealed (shown as 'Seal Length S') can be calculated using the equation shown in the diagram below.

| Recommended Radius For Convex Spring Curving | |||||

| Sheet Profile | BMT (mm) | Minimum Radius (m) | Purlin Spacing Minimum Radius* (mm) |

Maximum Radius† (m) | |

|---|---|---|---|---|---|

| Smartspan® | 0.42 | 20 | 1200 | 60 | |

| 0.48 | 20 | 1400 | 60 | ||

| CGI Corrugated | 0.42 | 12 | 800 | 35 | |

| 0.48 | 10 | 1000 | 35 | ||

| CGI Curving | 0.60 | 9 | 900 | 35 | |

*For radii curvature greater than the recommended minimum, the purlin spacing can be increased. However, the purlin spacing should not exceed the recommended maximum for straight sheeting given in Stratco product literature.

†Maximum recommended radius to provide sufficient drainage near crest of curvature.

Note: Please refer to Spring Curving in the Stratco Technical Guide for further information.

Spring Curved Concave Roofing

Sheeting can also be spring curved to the minimum radii shown in the table below to form a concave roof.

| Recommended Radius For Concave Spring Curving | |||||

| Sheet Profile | BMT (mm) | Minimum Radius (m) | Purlin Spacing Minimum Radius*(mm) |

||

|---|---|---|---|---|---|

| Topdek® | 0.42 | 24 | 1000 | ||

| 0.48 | 26 | 1400 | |||

| Smartspan® | 0.42 | 18 | 1200 | ||

| 0.48 | 20 | 1400 | |||

| Superdek® | 0.42 | 20 | 1000 | ||

| 0.48 | 22 | 1200 | |||

| CGI Corrugated | 0.42 | 10 | 800 | ||

| 0.48 | 10 | 1000 | |||

| CGI Curving | 0.60 | 8 | 800 | ||

*For radii curvature greater than the recommended minimum, the purlin spacing can be increased. However, the purlin spacing should not exceed the recommended maximum for straight sheeting given in Stratco product literature.

Fixing Requirements

Typically, standard fixing requirements will be adequate for spring curved roofing. In some cases, however, due to a combination of spring curving and thermal expansion effects, screws are susceptible to shear failure. The problem is most likely to occur towards the ends of the sheets which are fastened to heavy supports with little or no flexibility. In this situation large loads are transferred through the fixing points which can lead to roof sheets tearing or screws shearing.

In these cases, it is recommended clearance holes are drilled into the sheeting to allow movement of the sheets around the screws. Cyclonic washer assemblies would then be required to cover the clearance holes.