C and Z Purlins

StratcoSKU: C-and-Z-Purlins

Stratco manufacture a complete range of structural C and Z section purlins and girts for a wide range of applications. Made from quality, high tensile galvanized steel, Stratco purlins and girts can be supplied plain or punched. Whether you want to install them yourself or require assistance, we are here to help. Contact us for pricing and further details today.Image gallery

Quality Steel Purlins and Girts

Strong, reliable, high quality purlin and girt steel framing system

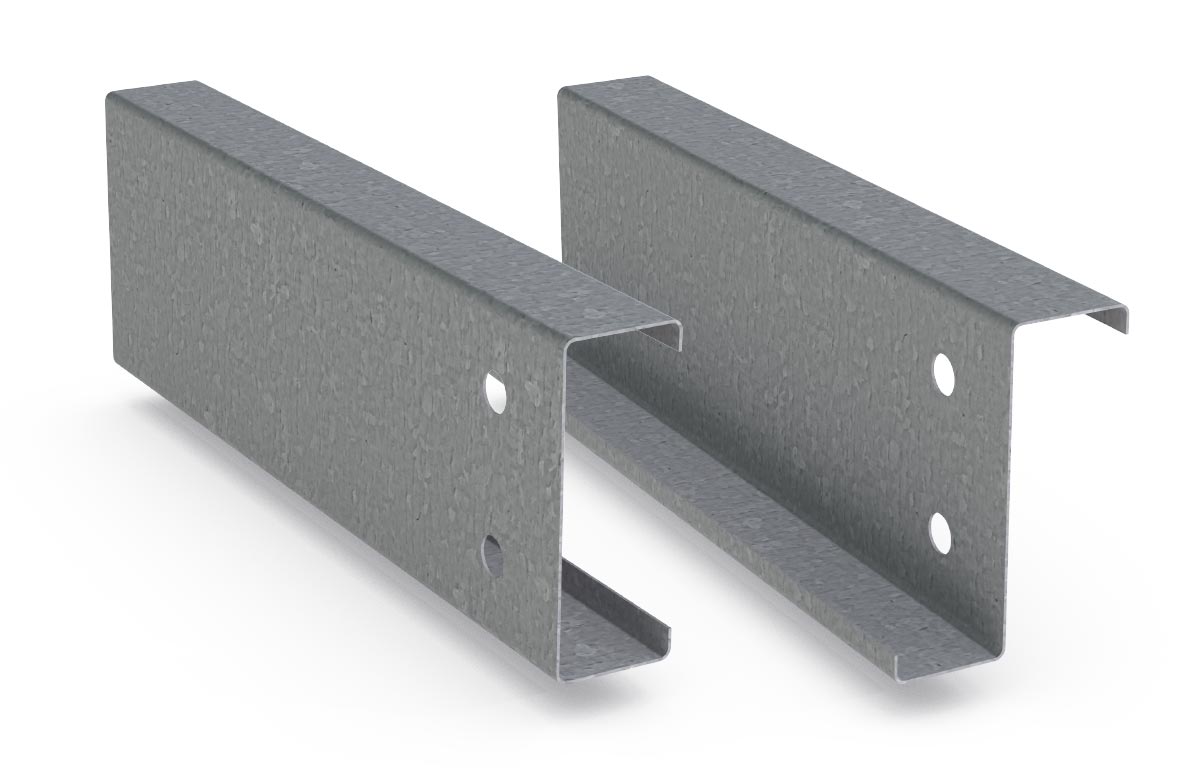

Stratco manufacture a complete range of structural C and Z purlins and girts for industrial buildings, garages, verandahs, and carports, in fact anywhere that strong, reliable steel framing is required. Manufactured from quality galvanised steel, this is a fully integrated system allowing for flexible design options.

Supplied plain or punched, galvanised purlins are manufactured from high tensile steel for increased strength, reduced weight, and a long serviceable life.

Brochures & Installation Guides

Extensive Range

Stratco produces an extensive purlin range with eight web heights and six thickness combinations, from 75mm to massive 400mm purlins capable of impressive spans. Fascia purlins are also available in the larger sizes. The following table shows the thicknesses available:

| Web Depth in Millimeters | ||||||||

| Thickness | 75 | 100 | 150 | 200 | 250 | 300 | 350 | 400 |

|---|---|---|---|---|---|---|---|---|

| 1.0mm | ||||||||

| 1.2mm | ||||||||

| 1.5mm | ||||||||

| 1.9mm | ||||||||

| 2.4mm | ||||||||

| 3.0mm | ||||||||

High Quality Purlins

Stratco purlins are crisp, clean and square and by any assessment are a quality product. There is no need to tolerate rounded corners, inaccurate lengths, or out of square purlins any more. Insist on quality Stratco purlins for your project.

Fast Service

Stratco offers an exceptionally fast service. Installation of new state of the art machinery allows not only faster production times, but greater flexibility to meet your needs. A guide to standard lead times can be seen in the table below: For larger projects, some additional time may be required.

Installer Friendly Bridging System

'Rapidfix' bridging is a very fast and easy to install system developed with your installer in mind. The receiver end has a unique locator tag that allows both ends to be held in place. Installation is easier and faster for the rigger who is operating well off the ground, often in windy and difficult conditions. Rapidfix will save both time and money.

Engineering Support

Stratco Engineers have carried out extensive testing on both purlins and girts, and on the 'Rapidfix' bridging system. Capacity tables have been calculated in accordance with limit state design principles and comply with Australian / New Zealand Standard AS/NZ 4600 : 1996 Cold formed steel structures, using software developed by the Centre for Advanced Structural Engineering at the University of Sydney. They are your guarantee of strength and structural sufficiency.

Competitive Price

Experienced technical Representatives are able to advise you on pricing and delivery requirements. Our pricing is competitive, and we ask only for the opportunity to provide a price for your next project.

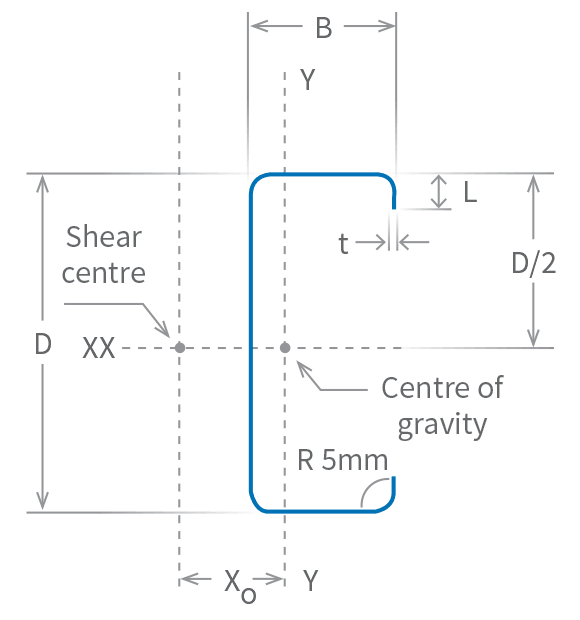

Profiles

C Section Purlin

Z Section Purlin

Material Properties

| Material Properties (MPa) | |||

| C Section Size |

Z Section Size |

Yield Stress fy |

Ult. Tensile Strength fu |

|---|---|---|---|

| 75-12 | - | 500 | 520 |

| 75-15 | - | 450 | 480 |

| 75-95 | - | 550 | 550 |

| 100-10 | 100-10 | 550 | 550 |

| 100-12 | 100-12 | 500 | 520 |

| 100-15 | 100-15 | 450 | 480 |

| 100-19 | 100-19 | 450 | 480 |

| 100-24 | 100-24 | 450 | 480 |

| 150-10 | 150-10 | 550 | 550 |

| 150-12 | 150-12 | 500 | 520 |

| 150-15 | 150-15 | 450 | 480 |

| 150-19 | 150-19 | 450 | 480 |

| 150-24 | 150-24 | 450 | 480 |

| 200-12 | 200-12 | 500 | 520 |

| 200-15 | 200-15 | 450 | 480 |

| 200-19 | 200-19 | 450 | 480 |

| 200-24 | 200-24 | 450 | 480 |

| 250-15 | 250-15 | 450 | 480 |

| 250-19 | 250-19 | 450 | 480 |

| 250-24 | 250-24 | 450 | 480 |

| 300-24 | 300-24 | 450 | 480 |

| 300-30 | 300-30 | 450 | 480 |

| 350-24 | 350-24 | 450 | 480 |

| 350-30 | 350-30 | 450 | 480 |

| 400-24 | 400-24 | 450 | 480 |

| 400-30 | 400-30 | 450 | 480 |

Dimensions

| Dimensions | ||||||

| t mm |

D mm |

Z Section | C Section | L mm |

Mass kg/m |

|

|---|---|---|---|---|---|---|

| E mm |

F mm |

B mm |

||||

| 0.95 | 75 | - | - | 40 | 10.0 | 1.26 |

| 1.2 | 75 | - | - | 40 | 10.7 | 1.59 |

| 1.5 | 75 | - | - | 40 | 11.4 | 1.97 |

| 1.0 | 102 | 53 | 49 | 51 | 12.5 | 1.77 |

| 1.2 | 102 | 53 | 49 | 51 | 12.5 | 2.10 |

| 1.5 | 102 | 53 | 49 | 51 | 13.5 | 2.61 |

| 1.9 | 102 | 53 | 48 | 51 | 14.5 | 3.29 |

| 2.4 | 102 | 53 | 48 | 51 | 15.0 | 4.13 |

| 1.0 | 152 | 65 | 61 | 64 | 14.5 | 2.42 |

| 1.2 | 152 | 65 | 61 | 64 | 15.0 | 2.89 |

| 1.5 | 152 | 65 | 61 | 64 | 16.0 | 3.58 |

| 1.9 | 152 | 65 | 61 | 64 | 17.0 | 4.51 |

| 2.4 | 152 | 66 | 60 | 64 | 18.5 | 5.67 |

| 1.2 | 203 | 79 | 74 | 76 | 15.0 | 3.62 |

| 1.5 | 203 | 79 | 74 | 76 | 16.0 | 4.49 |

| 1.9 | 203 | 79 | 73 | 76 | 19.0 | 5.73 |

| 2.4 | 203 | 79 | 74 | 76 | 21.0 | 7.20 |

| 1.5 | 254 | 79 | 74 | 76 | 18.0 | 5.16 |

| 1.9 | 254 | 79 | 74 | 76 | 19.0 | 6.50 |

| 2.4 | 254 | 79 | 73 | 76 | 20.5 | 8.16 |

| 2.4 | 300 | 100 | 93 | 96 | 28.0 | 10.09 |

| 3.0 | 300 | 100 | 93 | 96 | 31.5 | 12.68 |

| 2.4 | 350 | 129 | 121 | 125 | 29.0 | 12.20 |

| 3.0 | 350 | 129 | 121 | 125 | 30.0 | 15.19 |

| 2.4 | 400 | 129 | 121 | 125 | 28.0 | 13.16 |

| 3.0 | 400 | 129 | 121 | 125 | 30.0 | 16.39 |

| Web Depth in Millimeters | ||||||||

| Thickness | 75 | 100 | 150 | 200 | 250 | 300 | 350 | 400 |

|---|---|---|---|---|---|---|---|---|

| 1.0mm | ||||||||

| 1.2mm | ||||||||

| 1.5mm | ||||||||

| 1.9mm | ||||||||

| 2.4mm | ||||||||

| 3.0mm | ||||||||

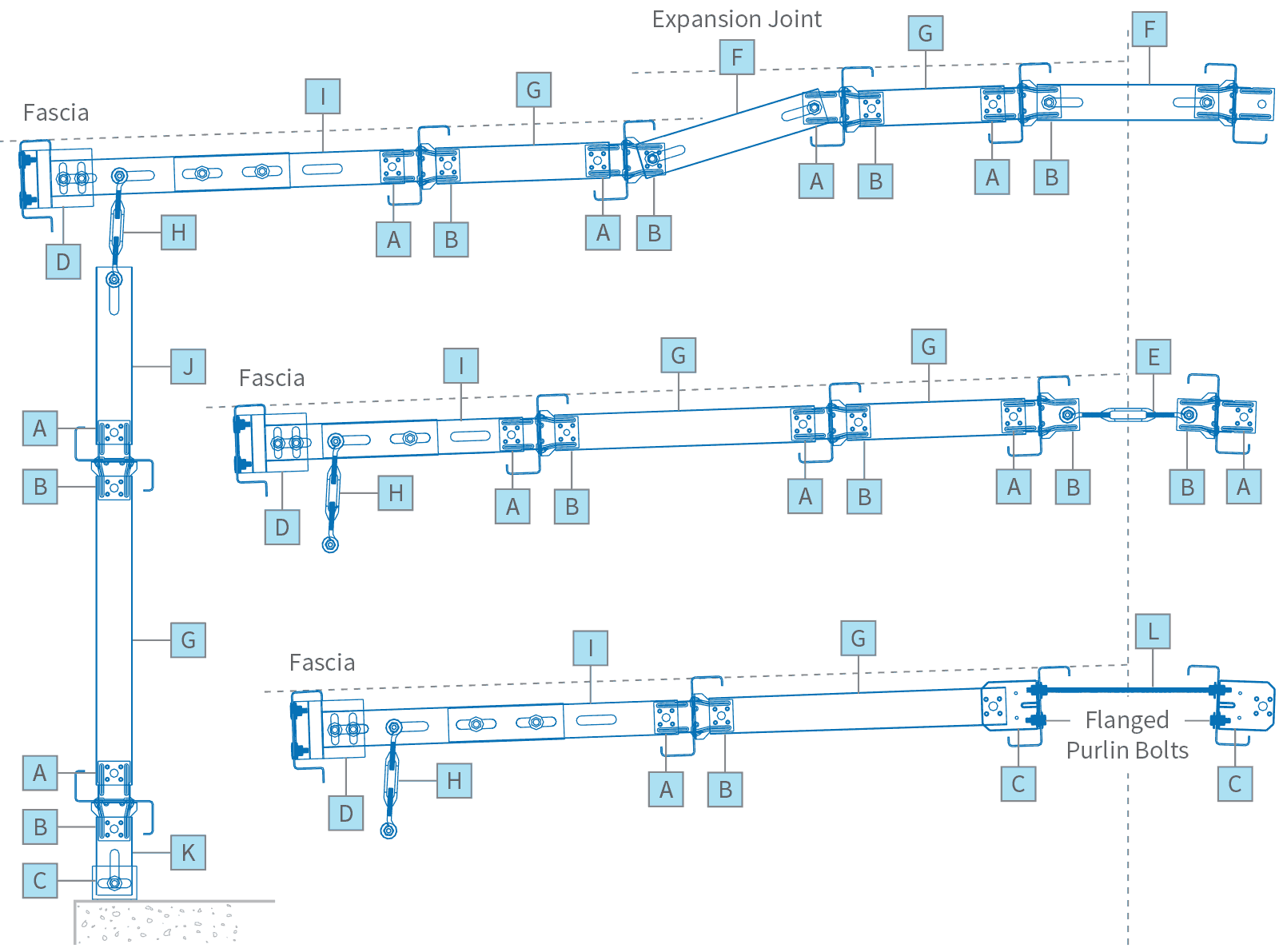

Typical Assemblies

A

B

C

A - Angle connector and Clamp Plate being used to anchor a C Section to a concrete slab floor.

B - Typical 90° connection using a General Purpose Bracket.

C - Simple connection to the open face of a C Section using an Angle connector and Clamp Plate.

Lapping

Figure 1

Figure 2

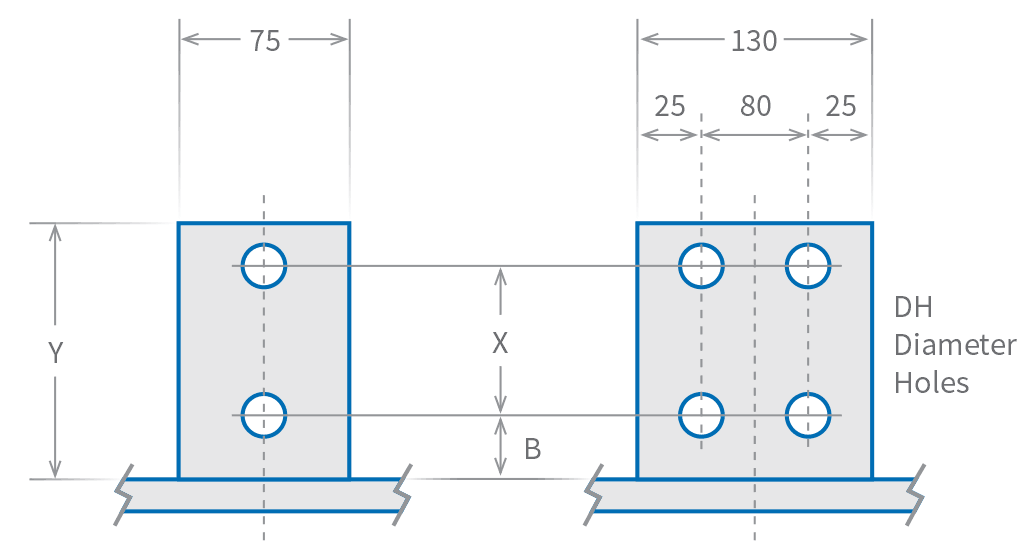

Fastening to Cleats

Hole Punching and Cleat Detail

| Cleat Nominal Dimensions (mm) | |||||

| Nom. Sec. Size | X | B | Y | Gap | DH |

|---|---|---|---|---|---|

| 100 | 40 | 40 | 110 | 10 | 18 |

| 150 | 60* | 55** | 145 | 10 | 18 |

| 200 | 110 | 55 | 195 | 10 | 18 |

| 250 | 160 | 55 | 245 | 10 | 18 |

| 300 | 210 | 65 | 305 | 20 | 22 |

| 350 | 260 | 65 | 355 | 20 | 22 |

| 400 | 310 | 65 | 405 | 20 | 22 |

Note: When using downturn lip purlins or girts, dimension B and Y must be increased by the length of the lip.

* 70mm in Victoria ** 50mm in Victoria

Z Purlin Standard*

Z Girt Standard

Z Girt Optional

C Purlin Standard*

C Girt Standard

C Girt Optional

* Z and C Section purlins must have the top flange pointing up the slope to minimise rotation.

Bridging Components

A - Locking End

B - Receiving End

C - Bolted End

D - Fascia Bracket

Bridging Assemblies

E - Ridge Bridging

F - Ridge Bridging Strut

G - Intermediate Bridging Strut

H - Turnbuckle

I - Adjustable Fascia Bridging

J - Girt Hanger

K - Girt Foot

L - Tie Rod

Bridging Configurations